Our Infrastructure

Assembly

100,000 class cleanroom

- CACPL is the first Indian company to leverage the finest ISRO-approved cleanrooms for the aviation industry. We adhere to strict guidelines to ensure the assemble quality

- Products assembled in clean rooms: High precision control valves & Modules, Airworthiness Motors and Actuators

| Spec | Value |

|---|---|

| Area | 114Sq.m |

| Humidity | 55±10% RH |

| Standard | Standard - ISO 14644-Class -8 (10,000) - FED STD 209E equivalent |

| Temperature range | 22+2°C |

| Particle Counts | <35,20,000 Particles (should not be more than 0.5 µ or larger) per cubic meter of Air |

| <29,300 Particles (should not be more than 5 µ or larger) per cubic meter of Air |

10,000 Class Cleanroom

- CACPL is the first Indian company to leverage the finest IRSO-approved cleanrooms for the aviation industry. We adhere to strict guidelines to ensure the highest assembly quality.

- Products assembled in clean rooms: High precision control valves & Modules, Airworthiness Motors and Actuators

| Spec | Value |

|---|---|

| Area | 228Sq.m |

| Humidity | 55±10% RH |

| Standard | Standard - ISO 14644-Class -7 (10,000) - FED STD 209E equivalent |

| Temperature range | 22+2°C |

| Particle Counts | <3,52,000 Particles (should not be more than 0.5 µ or larger) per cubic meter of Air |

| <2,930 Particles (should not be more than 5 µ or larger) per cubic meter of Air |

Horizontal Laminar Airflow Cabinet

- We have high-end horizontal Laminar Air Flow cabinets( 4 units) that effectively cleans the environment to suit product requirements (100 standard environment) of Ultra Clean environment

| Spec | Value |

|---|---|

| Area | 1170(L) X 610(W) X 560(H) mm |

| Standard | Standard - ISO 14644-Class -5 (100) - FED STD 209E equivalent |

| Particle Counts | <3,520 Particles (should not be more than 0.5 µ or larger) per cubic meter of Air |

| <29 Particles (should not be more than 5 µ or larger) per cubic meter of Air |

Coil Winding Machine (Dry and Wet)

- Semi-automatic programmable coil winding machine efficiently and flawlessly fulfil customer winding parameters (forms, multiple layers and other customization).

| Spec | Value |

|---|---|

| Winding Speed | 9000 rpm (max) |

| Spindle Nos. | 6 |

| Winding Width | 120mm |

| Bobbin Diameter | 75mm (Max. wire dia 0.2mm) |

| Wire Diameter | 0.35mm (Max. wire dia 50mm) |

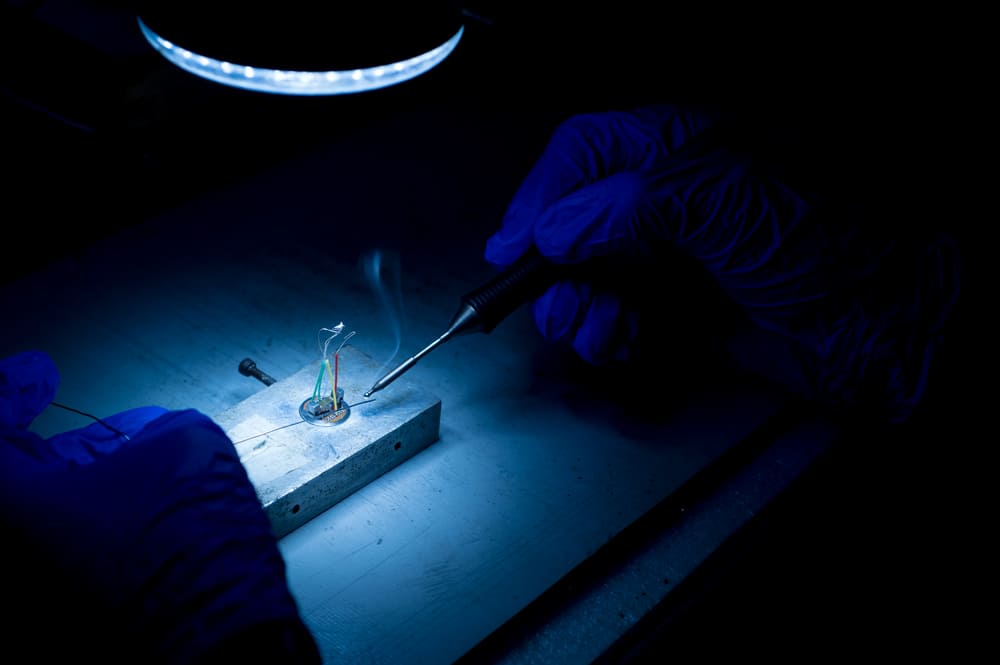

High Precision Micro Soldering Facility

- CACPL provides a dedicated micro soldering facility with IPC-A-600 Aerospace grade certified personnel to meet the standards of electrical and electronic circuits, assemblies, and parts in aerospace. Soldering process are done through dedicated industrial stereo microscopes with enhanced vision for better performance.

| Spec | Value |

|---|---|

| Processing wire dia | 9µ thick wire (Min) |

| Working Distance | 115mm |

| Personnel Certification | VSSC/ISRO & IPC-A-600 |

| Zooming Range | Upto 40x |

| Magnification | Upto 300x (with add on additional objective) |

Pressing & Crimping Facility

- CACPL has in-house crimping facility to be used for poppet and plunger crimping work

| Spec | Value |

|---|---|

| Max Load | 2.5 Ton |

Sheer brilliance and expertise in offering

incredible aerospace solutions.

SEND ENQUIRY