Our Infrastructure

Special Process

Our comprehensive special processes facility that includes:

Vacuum Furnace

- We offer Class 3 type B vacuum furnace in accordance with AMS 2750 to achieve process control, process repeatability with low impact to environment.

| Spec | Value |

|---|---|

| Class | 3 |

| Max. Temperature | 1300°C |

| Vacuum Level | 1 x 10-5 mbar |

| Loading Capacity | 30Kg |

| Hot Zone | 300 x 300 x 450mm |

| Quenching Pressure | Argon @ 2 Bar |

Muffle Furnace

- CACPL provides a Muffle furnace with world-class performance for glass to metal sealing, which has been certified for ISRO space missions and is utilised in the Transducer to place satellites into orbit.

| Spec | Value |

|---|---|

| Class | 5 |

| Max. Temperature | 1300°C |

| Heating Type | Resistance |

| Heating Element | Kanthal |

| Hot Zone | 250 x 150 x 250 mm |

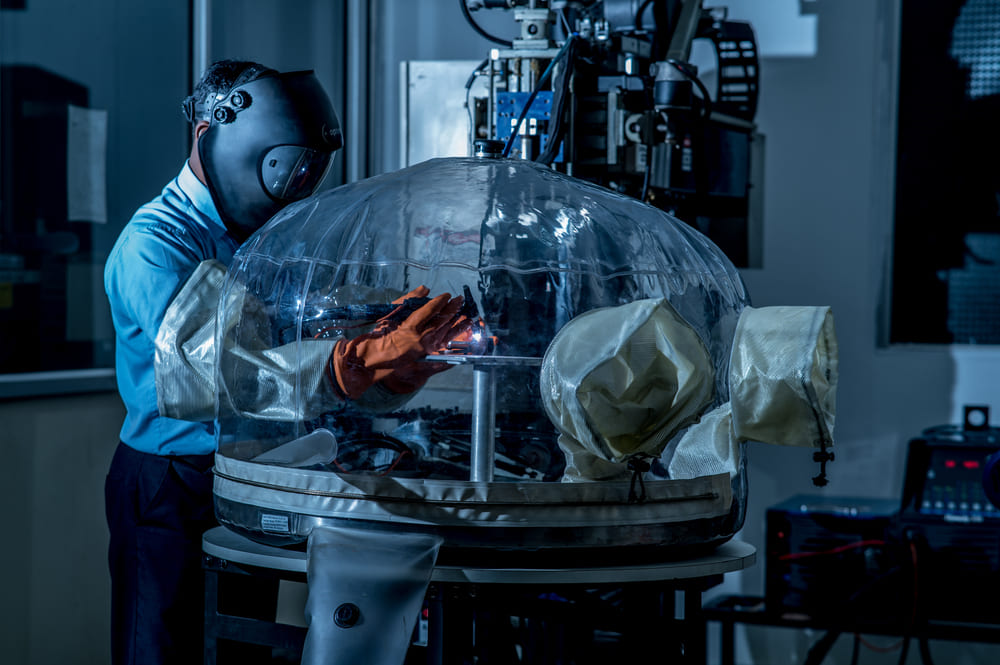

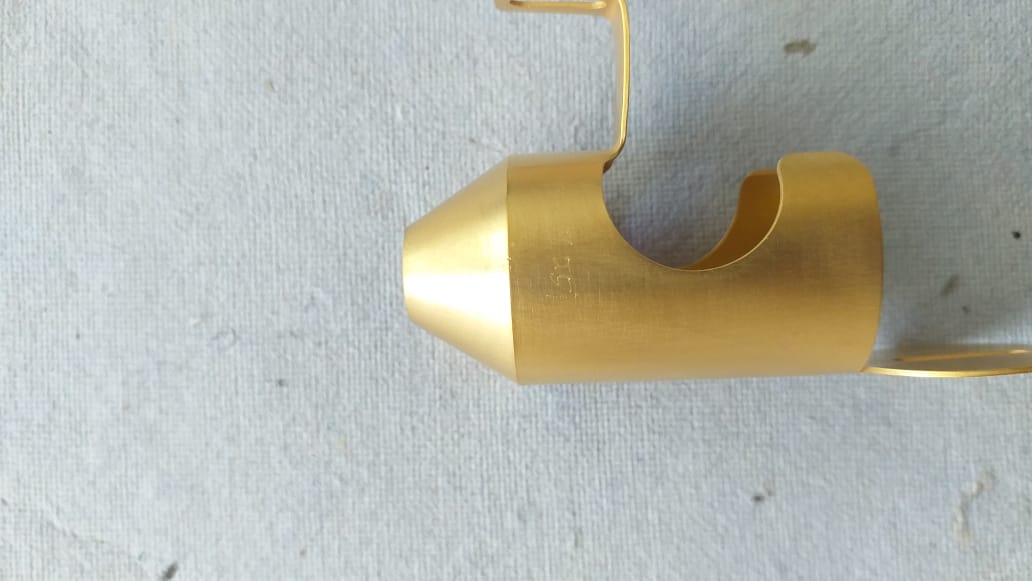

TIG Welding - GTAW

- CACPL has one of the best semi automated TIG welding facilites in the industry, with NADCAP certified, Honeywell approved and continuous three-year PRI merit award. We are well versed in Titanium welding.

| Spec | Value |

|---|---|

| Type | Dynasty 350AC |

| Welding Range | 0.350A |

| Coolant | Water |

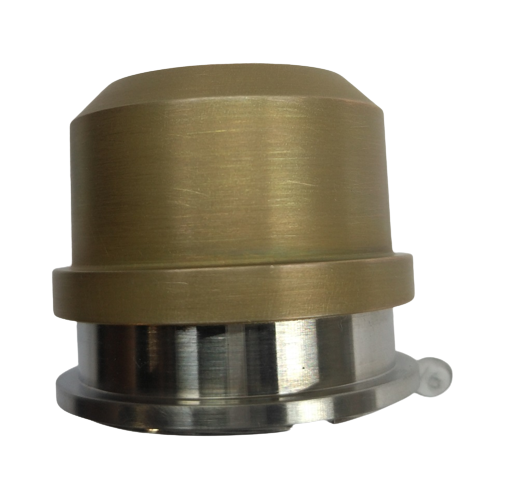

Electron Beam Welding

- We strengthend our welding portfolio by adding Electon Beam Welding machine under our roof and it's presence is very minimal in the industry. Our facility is NADCAP certified, ISRO, Honeywell approved and awarded continuous three-year PRI merit.

| Spec | Value |

|---|---|

| Chamber Size | 500(L) x 450(W) x 450(H) |

| Vacuum Level | Better than 5 x 10-4 TORR |

| Gun Travel | 200mm |

| Gun Power | 6KW |

| Beam Current | 100mA |

| Max Diameter | 200mm |

| Max Length | 180mm |

Ultrasonic Cleaning Facility

- Ultrasonic cleaning facility improves the efficiency of cleanrooms by eliminating all types of residues and loosened particulate matter from parts prior to assembly.

| Spec | Value |

|---|---|

| Cleaning tank size | 830x 300x 640 (L X W X H) mm |

| Overall Dimensions | 1000mm L x 450mm W x 1225mm |

| Tank Capacity | 125 Liter's Qty:1 No |

| Tank Material | SS 304 16G |

| Cleaning Frequency | 34 + 3 KHz |

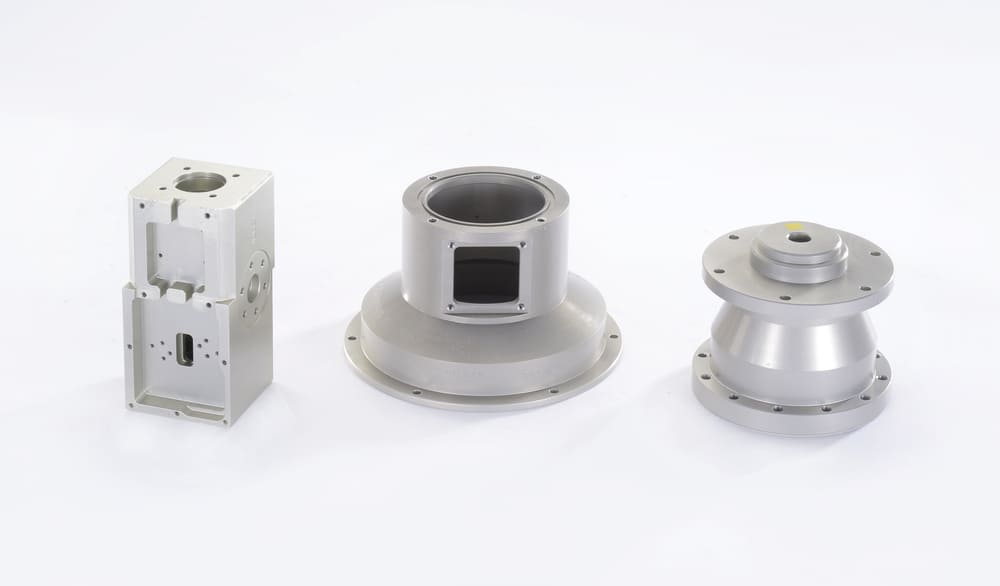

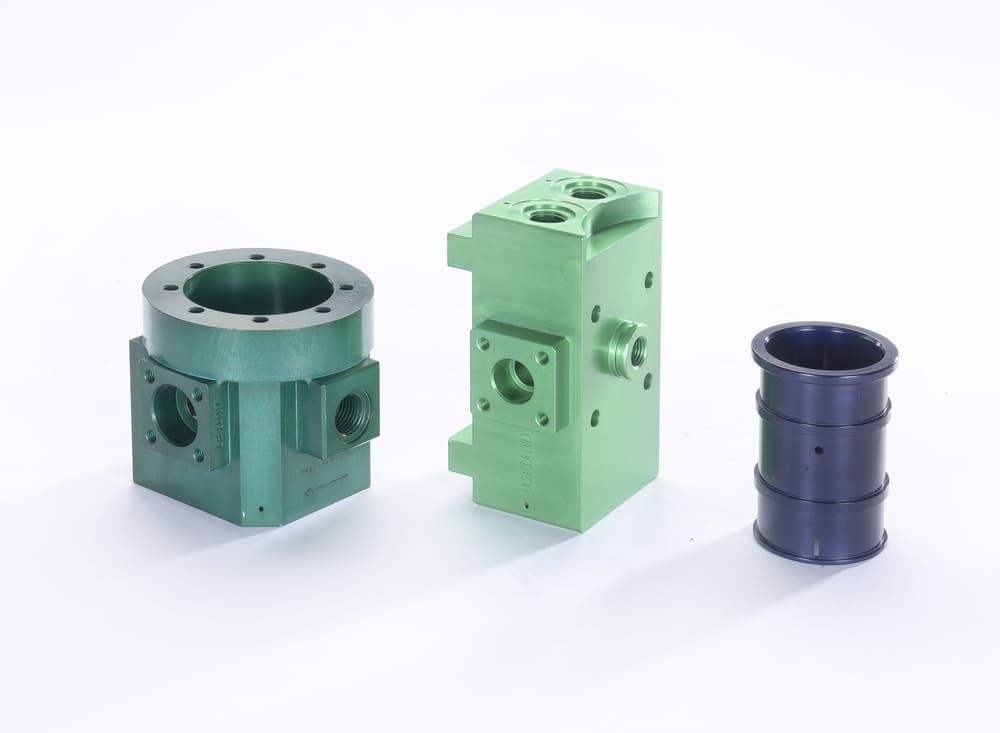

Anodization - Sulphuric Acid Type II & IIB

- CACPL has a surface treatment plant setup that offers Sulfuric acid anodizing services; the most widely used anodized coating solution in aerospace engineering.

- CACPL is Well versed to meet the speciifation of MiL-PRF-8625, AMS 2471, AMS 2472 and Our facility is NADCAP certified

Chemical Conversion Coating

- Nadcap certified hi-tech coating provided

- CACPL's chemical film coating process meets Mil-spec MIL-DTL-5541F, AMS 2473 requirements & Nadcap approved

- Excellent coating provided using hexavalent type of Alodine 1200S(Bonderite) and trivalent type Chemeon which ensures the qualified product list applied in QPL-81706.

Passivation

- Nadcap approved

- CACPL offers Nadcap approved industrial passivation services, used to remove impurities on the surface of stainless steel alloys

- Our services meet Nirtic based passiavtion as per ASTM-A967, AMS 2700 and QQ-P-35 & Nadcap apporoved specifications.

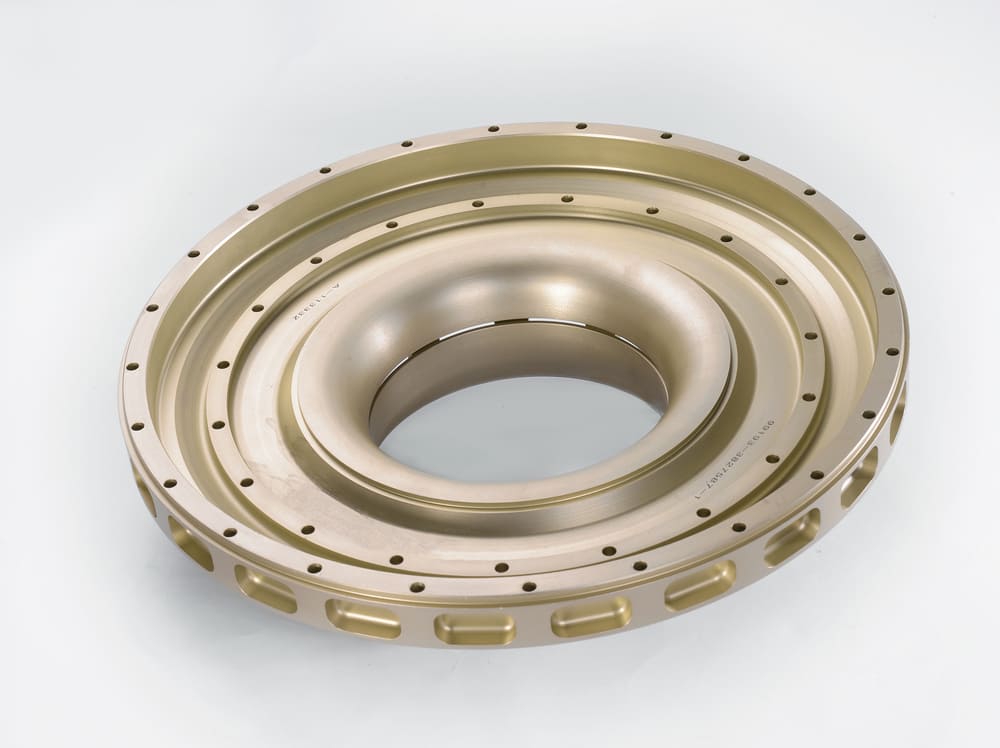

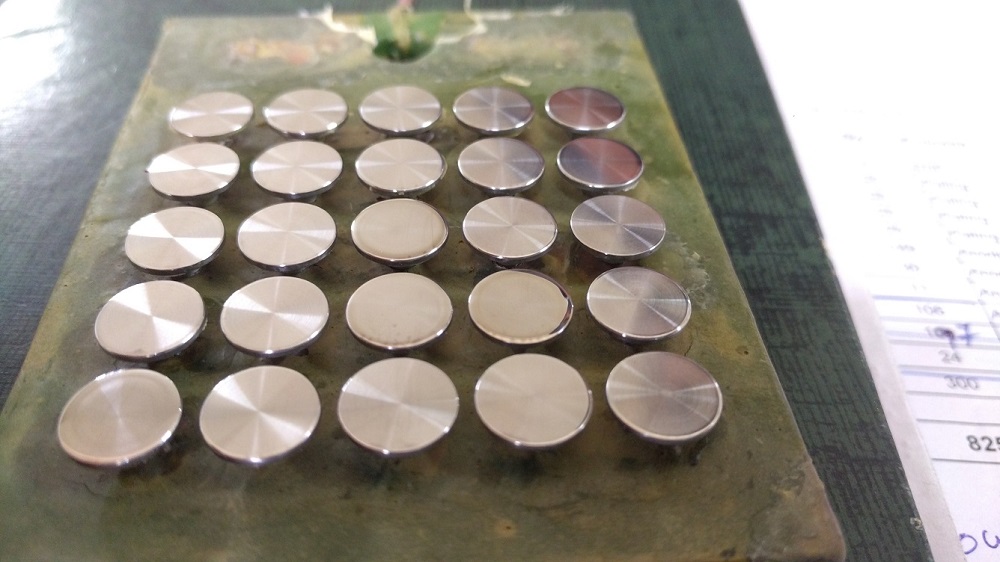

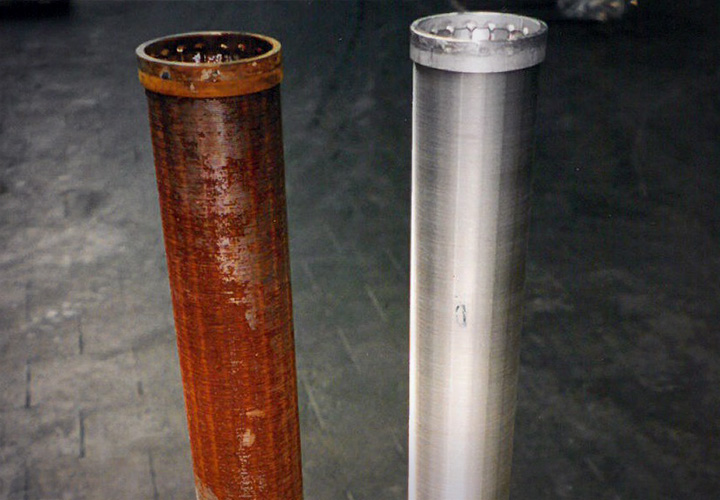

Electroless Nickel Plating

- Highly stable, consistent and easily controlled electroless nickel plating established as per the AMS 2404 specification & Nadcap approved

- The hardness after heat treatment acheviable to 900 - 1000 VHN

- CACPL is one of the company in India to get the Honeywell APSL apporval.

Electro - Cadmium Plating

- CACPL provide a aerospace-grade cadmium plating as per the AMS QQ-P-416 & Nadcap approved with capability up to 1 ft. in length

- AMS-QQ-P-416/QQ-P-416 type I and II,MIL-STD-870 standards.

Electro - Gold Plating

- CACPL specializing in high quality, 99.9 % purity of soft gold plating services for aluminum, steel and a variety of other materials for space application

- Soft gold plating is commonly used where the highest of gold purity is required for soldering, wire bonding, high temperature, biocompatibility or high corrosion resistance applications

- We offer our clients a superior product due to our attention to detail and commitment to quality, supported by the highest level of customer service which leads us to get the approval of ISRO, SAC-AHEMEDAHBAD

Electro - Nickel Plating

- CACPL offers Watts nickel plating which produces a semi-bright nickel deposit that excels in engineering and functional applications.

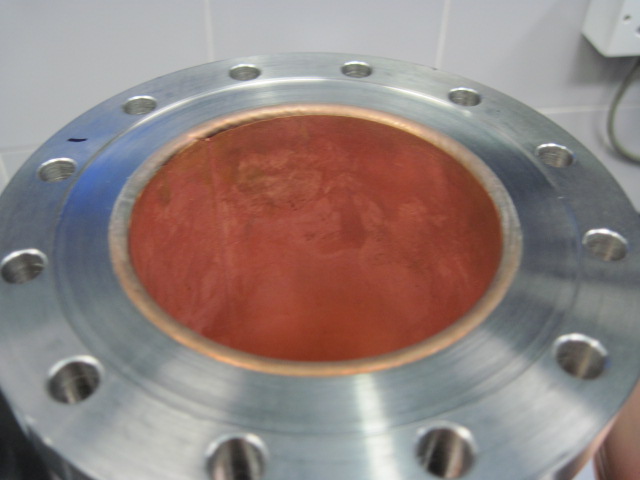

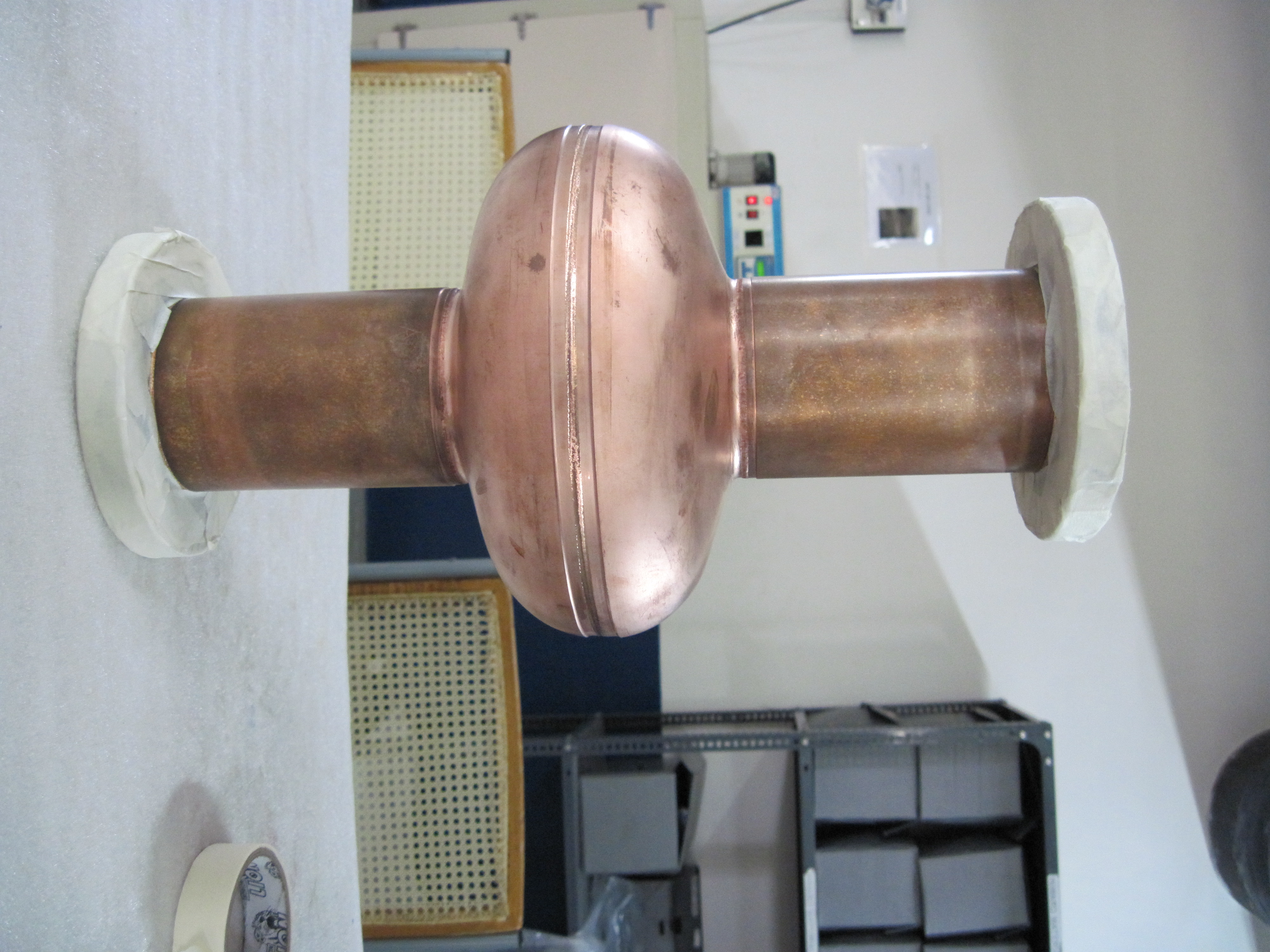

Electro - Copper Plating

- CACPL offers ISRO certified electro copper plating services which is a great source of conductivity at an economical price.

Pickling

- Pickling services are offered including ultrasonic, acid dip, metal derusting, descaling, aluminum bright dip, copper/brass bright dip, aluminium etch.

Chemical Etch Marking

- CACPL provides Chemical engraving services for the aerospace, defence and aviation and other industries, as per AS specification.

Sheer brilliance and expertise in offering

incredible aerospace solutions.

SEND ENQUIRY