Our Infrastructure

Machining

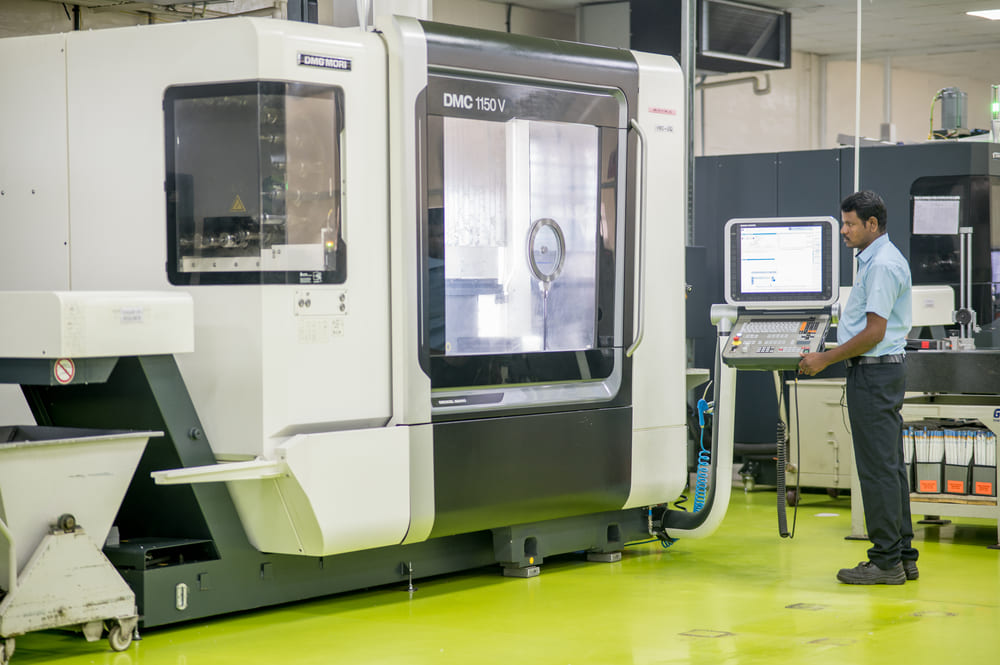

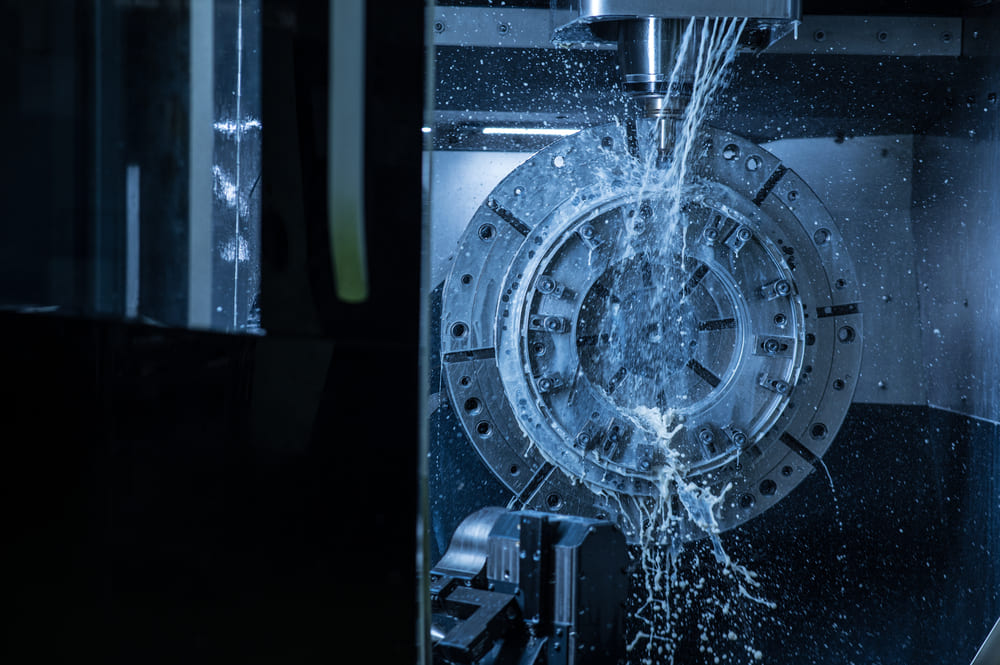

CACPL has a state-of-the-art machine shop capable of manufacturing complex components with the highest level of precision. Our machine shop is supported by industry veterans who contribute their expertise and employ some of the most precise and cutting-edge techniques for producing high-quality aerospace components. We create items to tight tolerances in a climate-controlled facility, and we attempt to foresee and overcome any challenges our components may face in the field.

To produce a streamlined workflow, the machine shop is planned out according to the Lean philosophy. Workplace 5S and TQM principles of Cleanliness and organisation are implemented.

Our machine shop has over 30 state-of-the-art DMG MORI machines to manufacture micron machining parts and maintain the highest level of dimensional and geometrical tolerances for Aerospace and Defense components. These include:

- 5 Axis machining centres

- 4 axis Machining centres

- 3 axis TurnMill centres and Turning centres

- High precision Swiss type turning machines from Schaublin, and Spinner

- High precision Sliding head type Turnmill centres from Manurhin, Tsugami & Good way

High Precision Swiss Type Turning Machines

- Schaublin

| Spec | Value |

|---|---|

| Turning Diameter | 0.5 - 115 mm |

| Tunring Length | 325 mm |

| Turning Diameter over bed | 200 mm |

| Spindle Passage | 24 mm |

| Tailstock quill taper MT | 3 |

| Turning speeds | 5000 1/min |

| Rapid power traverse in X and Z direction | 7.5 m/min |

| Turret (X Stations) | 8 (VDI 20) |

| Spindle motor | 7.5 / 5.5 kW |

| Control Unit | FANUC 18 A |

| Accuracy | Less than 5µ |

High Precision Sliding Head Type Turn Mill Centre

- Manurhin (collet type) ø 32.mm

- Tsugami (collet type) ø 26.0mm

- Good way (collet type) ø 32.mm

| Spec | Value |

|---|---|

| Machining Diameter | 3 - 32 mm |

| Spindle bore ø | 37 mm |

| Spindle power kW 100% / 25% - main | 5.5 / 7.5 kW |

| Spindle PassageSpindle power kW 100% / 30min. - counter | 3.7 / 5.5 kW |

| Spindle max. speed rpm - main | 10 000 min-1 |

| Spindle max. speed rpm - counter | 10 000 min-1 |

| Spindle stroke mm | 410 mm |

| Number of CNC axes | 6 + 2 |

| Programming channels | 2 |

| Tools in cut at the same time max | 2 |

| Live tools power kW | 2.3 kW |

High Precision CNC Turning Centres

- Pilatus 20T L5

- Pilatus 25T

- LL20T

- LL15T

| Spec | Value |

|---|---|

| Control | Siemens / Fanuc |

| Turning Diameter | 3 - 400 mm |

| Bed Width | 425 / 17 mm / in |

| Headstock Main Spindle Bore | 105 / 4 mm / in |

| Main Spindle Nose | A2-8 / D1-8 |

| Main Spindle Nose Taper | 5 MT |

| Speed Range | 425-1700 rpm |

| Working Feeds Z X | 0-7000 mm/min |

| Rapid Traverse Z | 10 m/min |

| Center Distance | 1000 / 40 mm / in |

| Tail Stock Barrel | 96 / 4 mm / in |

| Tail Stock Barrel | 215 / 9 mm / in |

| Tail Stock Morse | 6 MT |

| Stations of Standard Automatic Turret | 8 |

| Tool Shank | 32x32 / 1 1/4x1 1/4 mm / in |

| Boring Bar | 50 / 2 mm / in |

| Repeatability - 0.01 mm | 0.01 mm |

High Precision 3 Axis Turn Mill Centres

- DMG CTX Alpha-300

- DMG CTX Beta 500

- Tsugami

- Spinner

| Spec | Value |

|---|---|

| Main Spindle: Technology Integrated Spindle motor | |

| Machining Diameter | 0.5 - 250 mm |

| Speed | 5000 rpm |

| Power | 34 kW |

| C-Axis | 0,001° |

| Bar Capacity | 67 mm |

| Clamping Cylinder | Hollow clamping cylinder |

| Workpiece clamping | Hainbuch Axfix, Gr. 65 |

| Turret | 12 station, Sauter |

| Taper | VDI40 |

| Movement in X/Y/Z | 300/120/550 mm |

| Rapid Travers in X/Y/Z | 30m/min |

| Sub Spindle: Technology Integrated Spindle motor | |

| Power | 15kW |

| C-Axis | 0.001° |

| Speed | 6000 rpm |

| Bar Capacity | 52 mm |

| Repeatability | 0.01 mm |

| Positional Accuracy | 0.01 mm |

High Precision 4 Axis Machining Centres

- DMC 835V

- CMX 600VI

- DMC 1150

| Spec | Value |

|---|---|

| X Travels | 600 - 1150 mm |

| Y Travels | 560 - 800 mm |

| Z Travels | 510 - 610mm |

| Max Table Load | 600 kg |

| Table Length | 900 mm |

| Table Width | 560mm |

| Spindle Torque | 54 Nm |

| Tool magazine capacity | 30 |

| Positional accuracy | 0.01 mm |

| Repeatability | 0.01 mm |

High Precision 5 Axis Machining Centres / Mill-Turn

- DMU60 Monoblock

- DMU60 Evo

- DMC60 Evo linear

| Spec | Value |

|---|---|

| Travel X / Y / Z | 600 / 500 / 500 mm |

| Distance between spindle nose and table | 125 - 625 |

| Speed range | 20,000 rpm |

| Drive Power | (40 / 100 % ED) kW 35 / 25 |

| Torque | (40 / 100 % ED) Nm 130 / 87 |

| Tool Holder | DIN 69871 / DIN 69893 SK 40 / HSK-A 63* |

| NC Swiveling Rotating table | |

| Rotary table clamping area | 600 x 500 |

| Table load | 400 kg |

| Swivel range B-axis degree | (-)5 / +110 |

| Speed B / C-axis rpm | 60 /60 |

| Speed B- / C-axis torque table rpm | 80 / 150 |

| Rotation range C-axis degree | 360° |

| Speed mil turn table | 1200 RPM |

| Positional accuracy | 0.01 mm |

| Repeatability | 0.01 mm |

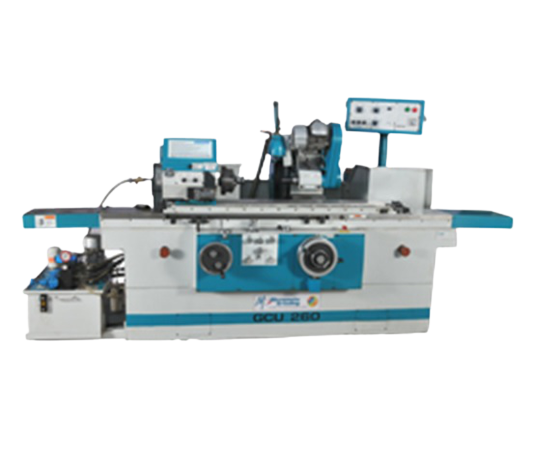

High Precision Cylindrical Grinding Machine

| Spec | Value |

|---|---|

| Swing Diameter | 260 mm |

| Admit between centers | 500/800/1200 mm |

| Max Grinding Wheel ɸ x Width | 400(500) x 50 (80) mm |

| Grinding wheel spindle power | 3.7 (5.5) kW |

| Wheel surface speed | 33 (45) m/sec |

| Accuracy | Less than 5µ |

Deburring Setup

- CACPL has 2 dedicated Deburring setup with certified personnels. Each machining component will be deburred with the help of industrial microscopes

Sheer brilliance and expertise in offering

incredible aerospace solutions.